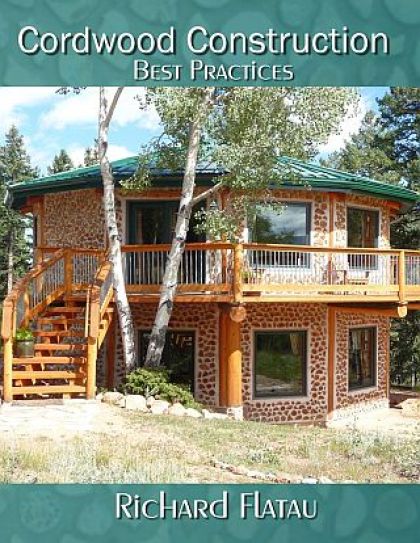

Having gazed longingly upon a cordwood cabin photo in a magazine years before, Carrie dreamed about building her own cordwood home. She read and gathered information and took one of our hands-on workshops. Feeling empowered to hit the start button, she built a gorgeous, energy-efficient, best practices cordwood home in western Wisconsin for under $50 @ square foot.  The white mason’s lines on each side of the cordwood wall, allow the builder to “sight” down the line. This keeps the wall in plumb.

The white mason’s lines on each side of the cordwood wall, allow the builder to “sight” down the line. This keeps the wall in plumb.  Bottle bricks are easy to make and lend a stunning statement to a wall.

Bottle bricks are easy to make and lend a stunning statement to a wall. The room-in-the-attic trusses are 10/12 pitch and allow for an extra 764 sq. ft. of space.

The room-in-the-attic trusses are 10/12 pitch and allow for an extra 764 sq. ft. of space.  The home sits into a hillside and the back wall and the two side walls are insulated and earth bermed.

The home sits into a hillside and the back wall and the two side walls are insulated and earth bermed.  A wood stove helps to regulate the temperatures on those cold Wisconsin nights.

A wood stove helps to regulate the temperatures on those cold Wisconsin nights.

The electrical is “run” up the middle of the posts and is “stubbed out” flush with the post. A receptacle plate or switch plate covers the wiring.

Board and batten gable end siding makes a good looking siding for a cordwood home.

The bathroom is completed in a rustic, country style and fits right in with the home.

The bathroom is completed in a rustic, country style and fits right in with the home.

The living room is comfy, cosy and has a beautiful view of the verdant valley below. Carrie wanted to make sure everyone knows that the house is not finished yet and she will send more pictures as she puts up trim and railings.

The first section of this “blog post” is dedicated to the beauty of the build. The section below (Section B) is about the real nitty-gritty of building.

Radiant in-floor heat pays dividends throughout the heating season. Heating your toes first is a gladsome feeling.

The foundation walls are covered with extruded styrofoam and a french drain with silt-sleeve extends around the perimeter to funnel water away from the foundation.

The poured walls and framing define the solid and massive structure.

LVL’s help with compression strength, wind load and structural integrity. They are loved by code officials. The notching of the post to accept the LVL makes for additional strength.

There is lots of work to be done before the first sticks of cordwood are mortared. Here the trusses are on, the dormers are cut and braced, the ice and water shield is on the roof and everything is braced.

Laying the subfloor on the trusses allows for safe work to continue on the second floor.

Incredible amounts of insulation were added to the roof in order to keep the warmth generated by the wood stove and the solar design, inside the home. There is a double insulation situation with R-38 and then another R-10 added.

When winter comes a calling, the home can be “boarded-up.” Work continues on the inside.

Finally, (an example of one of the Best Practices) this is why the roof is completed first so that the owner/builder can work out of the elements (the cordwood, materials and your crew remain dry).

[Note from Carrie: “I feel like I’m getting away with something– like it’s too good to be true that I have this beautiful home for so little money. You can post whatever you’d like (with the disclaimer that it’s not done?!?). Thanks again for everything!!!”]

[Editors comment: There are so many things Carrie did so very well (besides the beautiful random pattern cordwood and bottle ends), that other people could learn from. For Example; the LVL’s, the French drain, the truss room-in-the-attic, poured/insulated foundation walls, the earth berm, attaching window boxes to posts, board & batten siding, metal roof, etc. Good use of space, good design, dormer in the middle of the truss, well-insulated trusses, good random pattern cordwood infill, posts notched for LVL’s. So many best practice concepts to share. Thank you again for documenting your success.]

Should you wish to learn how to build a cordwood cottage, cabin or home, please visit www.cordwoodconstruction.org While you are there, click on the pictures, read the brief articles, check out the latest workshops and newsletter and if you are interested click on the Online Bookstore to see all the cordwood literature available in print, video and ebook format.

If you have questions that aren’t answered on the website you can email me at richardflatau@gmail.com

Readers have requested a brief bio, so here goes:

“Richard & Becky Flatau built their mortgage-free cordwood home in 1979 in Merrill, Wisconsin. Since then, they have written books, conducted workshops, facilitated the 2005, 2011 and 2015 Cordwood Conferences and provided consultation for cordwood builders. Cordwood Construction: Best Practices DVD, Cordwood Construction Best Practices (print) and Cordwood Conference Papers 2015 are the newest publications available from their online cordwood bookstore. www.cordwoodconstruction.org

Click on the picture if you would like to order this “best of the best” DVD.